ELECTROMAGNETIC BRAKE SYSTEM

SELECTION OF SUITABLE MODEL

The Brakes are rated by torque and selection of the suitable model can be made by calculating the required torque rating of the Brake and then matching it with the static torque rating. Although the calculation of torque is based on various factors an approximate evaluation can be made using the following formula.

- Torque (NM)= [9550x (K.W. R.P.M.)] x Safety factor (sf)

- where K.W. - Kilowatts of Motor, R.P.M.-Speed at Brake location.

- (sf) = Safety factor depending on type of prime mover and load.

- For Electric Motor-2 to 3

- Diesel Engine - 4 to 5

- Compressor-5 to 6

- However we recommend that you may please kindly contact us for literature on detailed calculation for selection of Brake.

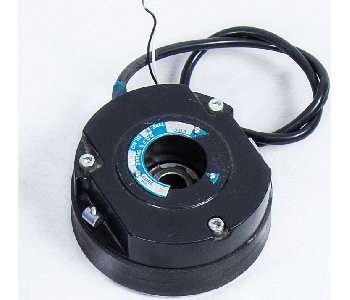

OPERATION

The Brake is designed to ensure safety due to the Braking torque being always applied by means of pressure springs when no voltage is applied to the brake and it is thus normally in ON condition. Upon Energisation of the Electromagnet (1) by applying a D.C. Voltage the Armature Plate (2) is pulled towards the Electromagnet thus loading the pressure springs and allowing the Disc (4) which is axially movable on the Hub (5) to rotate freely. When the current is stopped the pressure springs push the Armature Plate towards the disc which in turn is pressed against the mounting flange or friction plate or the motor cover itself which is stationery and thus the Rotational movement is stopped due to friction, thus Braking the motor shaft.

ASSEMBLY

The preceding drawing shows the assembly of the Brake Type 'K' Place the Armature Plate(2) and the Electromagnet (1) in which the torque springs should be inserted. Fix the fixing screws (9) on the Mounting Flange. The Mounting Flange should be made of steel or cast iron and have a flat surface machined with 1.6 Ra. Roughness. If the Brake is supplied preassembled, remove the air gap adjusting device after mounting the brake. The braking torque can be adjusted by operating the adjusting ring (7). Note: Please ask for detailed literature on mounting of the brake, for Air gap adjustments, Braking torque adjustment etc.

ELECTROMAGNETIC BRAKE SYSTEM

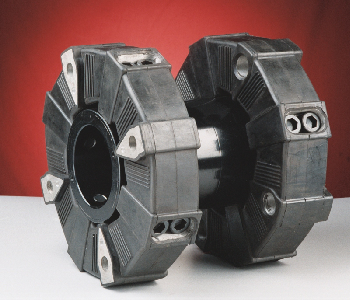

Optional Attachments

Dust Seal

It prevents penetration of dust or other fragments into the braking area. The dust seal is pulled over the brake and inserted into the grooves provided.

Hand Release

The hand release, releases the brake manually and it automatically goes back into its original position after operating.

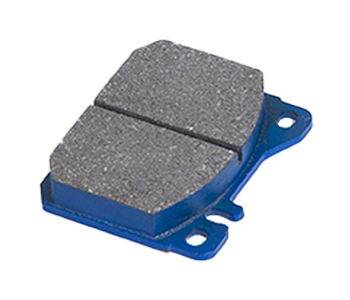

Friction Plate

We recommended to use the friction plate when a plain machined counter face is available but cannot be used as a friction surface. The friction plate can also be combined with the dust seal.

Mounting Flange

We recommend to use the mounting flange when no suitable friction surface is available. It can also be combined with the dust seal.

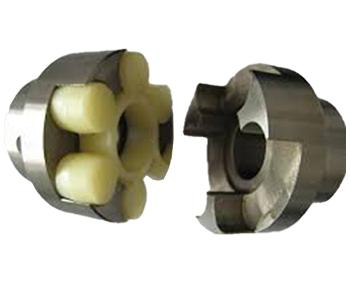

Other Products

*For all products, customization based on your requirement (size and dimension) can be made

Enquiry

Quick Enquiry

© ARR KAY - 2023 | All Right Reserved. Designed By Kambaa Inc

.jpg)

.jpg)

.jpg)